If you are a distributor looking for commercial wood doors, you may be asking yourself, “How do I determine the quality of my wood door? How do I identify my door manufacturer?” You want to provide your customers with durable, high-quality doors available in a variety of styles and sizes. Everything from the size of the hardware to the material of the door is up to your discretion, and the choices you make about the material, core and hardware of the doors will impact the benefits they can provide to customers.

To help you determine the overall quality of your door, we at Manhattan Door have compiled this guide to walk you through the entire process and the properties of different types of wood. From identifying the quality of the door material to the door core and the door hardware, here is everything you need to know when picking the right wood door for your business.

How can you tell if a door is made from quality material? The criteria for quality material depend on the material. There are various types of door materials, which include laminate, veneer and paint grade. Each type comes with unique specifications that cater to a specific budget and audience.

For an affordable, versatile door option, you may want to consider a laminate door. Decorative laminate doors have consistent, durable designs that make them a popular option for commercial or high-traffic spaces, such as schools and hospitals.

The following are benefits of laminate doors:

At Manhattan Door, we design our flush plastic laminate doors to ensure durability through high-frequency use. These doors can be designed in customized sizes up to 48 inches by 120 inches and are fire-rated up to 90 minutes. Additionally, we offer a wide variety of design options to tailor laminate door, including wood grains, solid colors, abstract patterns and styles. Our laminate doors can be installed in several different work environments, such as offices, warehouses, municipal buildings, retail centers, auto shops and more.

How can you tell if the laminate is quality laminate? Check the door material. The material should not produce an unpleasant odor, the frame should be level, and there should not be any visible dents or scratches. You can also check the accessories to ensure all the elements are fastened securely.

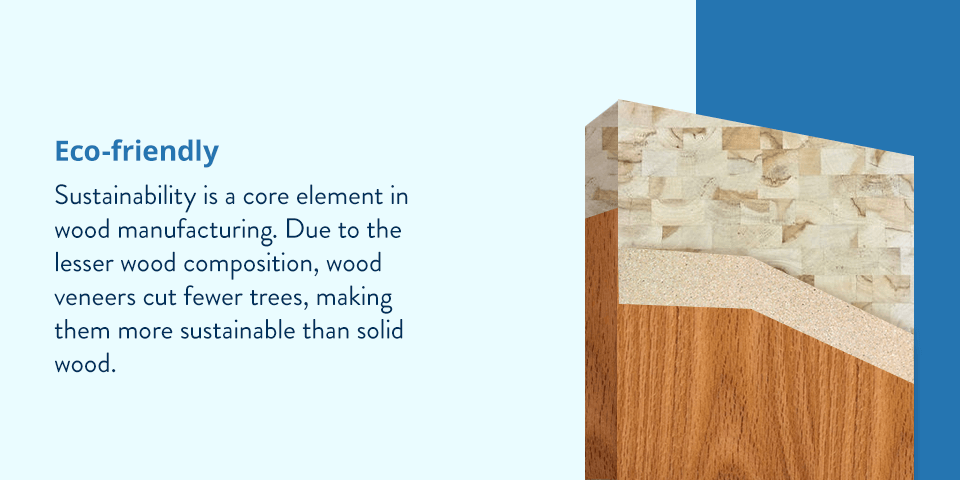

If you want an affordable door option without sacrificing beauty, veneer interior wood doors may be the right option for you. The following are the benefits of wood veneer doors:

Wood veneer can provide excellent quality, durability and insulation. These doors can be made from various types of wood, such as oak, cherry, mahogany, maple and walnut. Additionally, you may want to select a wood veneer door that has a durable stain and a clear finish. A finish can prevent your door from absorbing moisture or swelling.

Common veneer cuts include:

Our veneer doors are manufactured to your specifications, which includes customizing your door to fit the exact opening size. Select any common or specialty species of wood or a certain factory finish for an attractive and distinct professional appearance. Wood veneer doors can offer visual appeal and lasting performance at a cost-effective rate. Many wood veneer doors are corporate settings, hotels and hospitality venues.

How can you tell if the veneer is high quality? During quality control, veneer doors are inspected for knots or rot sections. Other materials used during construction must also meet certain standards of quality, such as the glue and stains. A quality veneer door should keep swinging for years and resist warping.

To determine if the wood is high quality, you can first check the package integrity, looking for opened or torn packaging. You can also compare your door to the presented model and examine the heat and sound insulation.

Wood doors are also available in paint grade. Here are some of the benefits of paint grade doors:

At Manhattan Door, our paint grade options can complement any interior design. We use a fast-drying, water-based latex primer that works well in both exterior and interior applications. With all of our options, you can add a clean, professional paint grade door to any building.

Are solid core doors worth it? Or should you select a hollow core door? Solid core and hollow core doors differ in insulation, sturdiness, sound blocking and maintenance. Knowing how a door is constructed is helpful when it comes to decorating or making repairs.

Solid core doors are constructed from natural wood and synthetic material, and they more closely mimic real wood than hollow core doors. While hollow core doors tend to be a more affordable option, they are less durable than solid core doors.

We at Manhattan Door offer the following types of interior door cores:

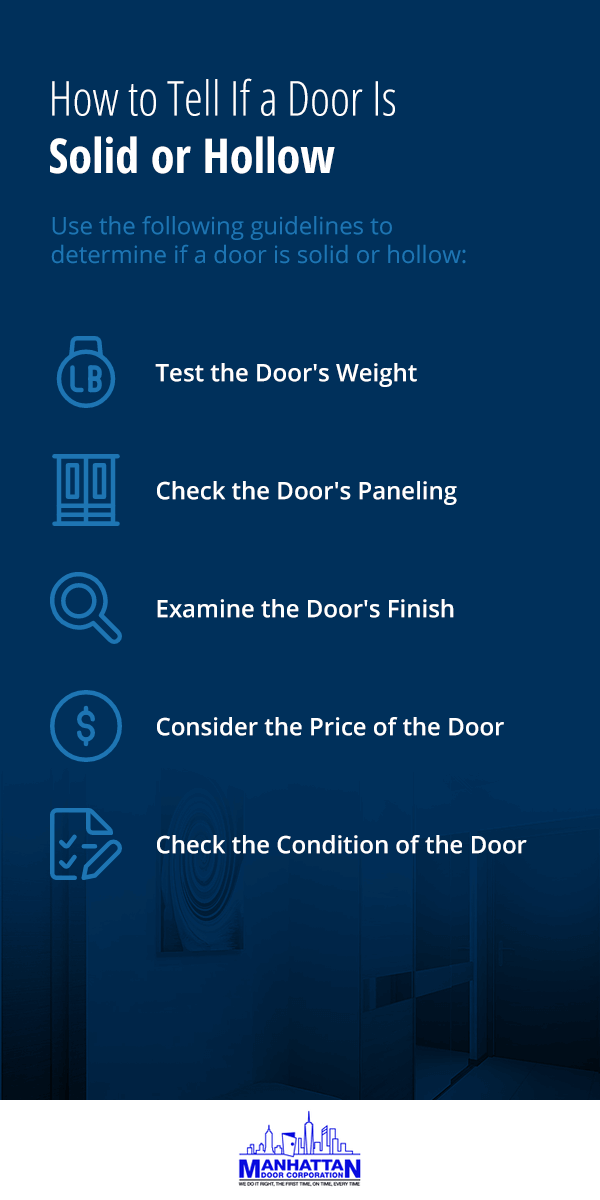

Use the following guidelines to determine if a door is solid or hollow:

If the door is new and has not been hung yet, you can test it by how easily you lift the door. For a door that is already attached, you can swing it open and closed to test the inertia. Hollow core doors can be lifted and swung quite easily, while solid core doors are quite a bit heavier and will be more difficult to lift. If the door requires minimal effort to lift or swing, there is a high chance that it is a hollow core door. If the door requires more effort to lift or swing, it is probably a solid core door.

If there is paneling on the door, it may help you determine whether a door is solid core or hollow core. Hollow core doors tend to have faux panels, and a close examination can tell you whether the panels are imitations. If the panels on the door appear real and detailed, then it is likely a solid core door.

The finish on a door can also help you determine whether the door is hollow core or solid core. Hollow core doors are not often stained by manufacturers, except for veneer doors. If a wood door is stained, then it is more likely that it is a solid wood door than hollow core, particularly if the door is heavy. If the door is painted, then it is likely a hollow core door.

Hollow core doors tend to be less expensive than solid core doors. Prices can vary by manufacturer and location, so speak to a salesperson who can give you an idea of the price points you can expect for different door cores. Solid core doors typically have a higher price point because of the resources used as well as the detailed construction process. As a result, solid core doors are sturdier while providing more insulation and security.

A solid core door uses denser materials, which makes it more durable than a hollow core door. The solid construction of solid core doors also impacts its life span. If a wood door has dents or holes from normal wear and tear, then it is likely a hollow core door. If the door does not have any damage, this does not necessarily mean it is definitely a solid core door, but damage likely means it is a hollow core door.

Hardware for a door serves multiple purposes, including adding beauty, securing a property and providing convenience. The following are different hardware types for doors:

Doorknobs and levers are necessary for opening, closing and securing a door. A latch in the doorknob disengages when the knob is turned. When the doorknob is locked, the latch cannot be disengaged from the outside unless a key is used. A door can be locked and unlocked with the thumb turned on the inside of the knob. Some doorknobs have locks that can be disengaged when the inside knob is turned, and others feature a push-button that can lock the door on the inside.

Door levers are intended for easy operation, as they do not need to be grasped and twisted like doorknobs. Instead of a lever, the user needs to only push down the lever to disengage the latch. Locking a lever prevents anyone from disengaging the latch from the outside unless a key is used. Door levers can also be right-handed, left-handed or universal.

Handlesets can add a decorative touch to a door. These include a thumb-operated latch, a deadbolt and an exterior handle. Similar to door levers, handlesets can be found with left-handed, right-handed and universal levers. The deadbolt of the handleset can be either single-cylinder or double-cylinder. Nonfunctional handsets are also available to complement a double door’s functional hardware. A handleset can give a door more elegance compared to the average deadbolt and doorknob or door lever.

Deadbolts are another type of door hardware. When paired with a locking doorknob or door lever, a deadbolt functions as another locking point. A deadbolt can provide an additional security measure and more peace of mind. Deadbolts are available as either single-cylinder or double-cylinder.

We at Manhattan Door focus on providing distributors with quality wood doors. We have more than 80 years of combined experience in building and designing interior wood doors. Our friendly, knowledgeable sales team will help you choose wood door products to best serve your clients’ needs. We manufacture each order according to our customers’ exact, unique specifications. Additionally, we offer rush orders with a standard lead time of two to three weeks. If you need to distribute quality wood doors with a tight timeline, we can help you.

If you are looking for an interior wood supplier in the Tri-State area, we are a family owned and operated manufacturer that can provide you with exceptional, dependable service and high-quality products. We do it right. The first time. On-time. Every time. Contact us at Manhattan Door today and canvass the right type of wood for your business.